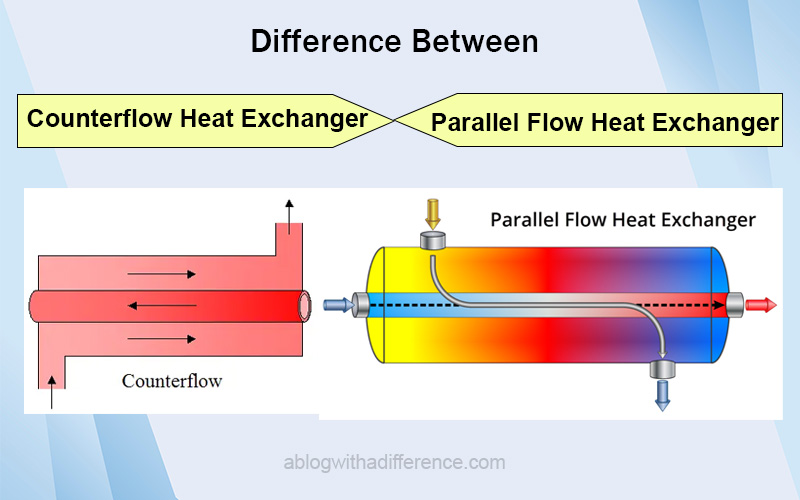

Difference Between Counterflow and Parallel Flow Heat Exchanger

Brief Overview of Counterflow and Parallel Flow Heat Exchanger

Counterflow and Parallel Flow Heat Exchanger are two popular devices used to transfer heat between fluid streams.

Counterflow heat exchangers feature hot and cold fluids flowing in opposite directions to maximize efficient heat transfer as their temperatures differ considerably during exchange. As they clash against one another, heat transfers from hotter fluid to cooler fluid resulting in an overall temperature change for both streams.

On the other hand, parallel flow heat exchangers feature both fluids moving in unison towards each other in their pathways – their paths running parallel. Fluids enter at one end and travel parallel paths before coming together again at their destinations to allow heat exchange to happen; however, their temperature differences gradually reduce along their flow path, which results in lower overall heat transfer than with counterflow exchangers.

Counterflow and parallel flow heat exchangers each offer distinct advantages and drawbacks, with counterflow heat exchangers tending to offer better heat transfer efficiency due to their sustained temperature difference between fluids compared with parallel flow heat exchangers with diminishing temperature differential.

While counterflow heat exchangers typically boast superior transfer efficiencies due to sustained temperature differential, their complex designs usually require larger physical footprints; on the other hand, parallel flow heat exchangers tend to have simpler designs, require lesser physical footprint, and generally have reduced efficiency due to diminishing temperature difference between fluids being exchanged.

Engineers often consider various factors when selecting an optimal heat exchanger type and model configuration for any given application, including required transfer rate, available space requirements, fluid properties requirements, and costs associated with different configurations. They then make recommendations based on these parameters to select an ideally suitable configuration that fulfills those parameters.

Counterflow Heat Exchanger

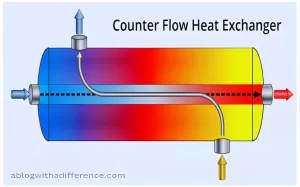

Counterflow heat exchangers are heat exchangers where two fluids flow in opposite directions. Here, hot fluid enters at one end while cold fluid comes through at the other; once inside they meet one another and exchange heat through walls or surfaces that separate them.

Counterflow heat exchangers boast many advantages. First, they provide efficient heat transfer by maintaining temperature differences between hot and cold fluids throughout the exchanger – creating an overall higher heat transfer coefficient. These exchangers can achieve large temperature differences across their exchanger, making them useful in applications which necessitate significant exchange.

Counterflow heat exchangers tend to require less materials and energy compared to other forms of heat exchangers, due to temperature gradients allowing a smaller heat transfer surface area and, hence, material requirements; additionally, due to counterflow configuration enabling smaller temperature gradients across walls for reduced energy losses.

Counterflow heat exchangers do have some drawbacks; when used for applications where freezing could potentially happen – such as refrigeration systems – there is the risk of freezing fluid if its temperature gets too cold during heat exchange process. Also, these exchangers typically feature higher pressure drop than parallel flow versions which may hamper overall system performance or require additional pumping power to function optimally.

Parallel Flow Heat Exchanger

Parallel flow heat exchangers are an efficient form of heat transfer where two fluids flow in parallel within an exchanger, such as entering from opposite ends before emerging at opposite points on its length. To use one, two hot or cold fluids enter at their respective entrance points before travelling parallel along its length before exiting at opposing exit points.

Parallel flow heat exchangers offer many benefits. One major one is providing uniform temperature distribution across their exchanger as fluids flow in one direction; as this occurs, temperature differences between hot and cold fluids decrease gradually along their length – this makes parallel flow heat exchangers ideal for applications where uniform temperature distribution is desired, such as air conditioning systems.

Parallel flow heat exchangers offer another advantage over counterflow heat exchangers: typically lower pressure drop. This means fluids encounter less resistance as they flow through, ultimately leading to reduced energy use and improved system performance.

Parallel flow heat exchangers are ideal for applications where there is only a minimal temperature differential between hot and cold fluids; such as when heat recovery systems or certain kinds of heat pumps require limited heat transfer.

Parallel flow heat exchangers do have some drawbacks. One such drawback is their lower overall efficiency compared to counterflow heat exchangers; as temperature differences between fluids reduce when they flow in parallel direction, leading to reduced driving forces for heat transfer. Parallel flow heat exchangers typically require larger surface areas for heat transfer than counterflow configurations and could increase material and cost requirements significantly.

What is the principle of counterflow Heat Exchanger ?

Counterflow heat exchangers rely on two fluids moving in opposite directions to exchange heat with each other. They enter from opposite ends of an exchanger and eventually meet at one. Heat is transferred via walls or surfaces between these fluids that serve as separators between their flow of fluids.

Counterflow operates under the principle that there must be an extreme temperature difference between both liquids. As they travel in opposite directions, hot fluid transfers its heat to colder fluid, which gradually absorbs it as temperatures gradually increase over time. This constant heat transfer mechanism results in efficient heat exchange.

Counterflow maximizes temperature difference between hot and cold fluids, leading to an improved heat transfer coefficient and more efficient transfer of thermal energy between them. Its opposite flow direction also contributes to maintaining larger temperature differences across the heat exchanger resulting in better heat transfer performance.

Counterflow heat exchangers utilize the principle of counterflow for effective heat transfer with large temperature differences and reduced energy needs, making them suitable for various industries such as HVAC, power generation, chemical processes and refrigeration.

What is the principle of Parallel Flow Heat Exchanger?

Parallel flow heat exchangers work by channelling two fluids in opposite directions in an enclosed container. Both hot and cold fluid enter from one end before traveling along parallel tracks until exiting at opposite ends.

Parallel flow relies on fluids experiencing gradual temperature equalization while flowing in parallel; by moving at similar rates through an exchanger, any differences in temperatures become smaller as time progresses.

Parallel flow heat exchangers allow hot fluids to transfer heat directly into cold fluids as they flow side-by-side, through walls or surfaces which facilitate thermal energy transmission from hot to cold fluids.

Parallel flow heat exchangers offer more even temperature distribution throughout the exchanger as fluids travel together, their temperatures gradually equalizing as they pass each other by way of convection currents. This uniform temperature distribution can be advantageous when maintaining consistent temperatures throughout the process – such as air conditioning systems.

Though heat transfer efficiency of parallel flow heat exchangers tends to be lower when compared with counterflow configurations, they offer various advantages over their counterflow counterparts, including lower pressure drop and suitability for applications with smaller temperature differences.

Parallel flow heat exchangers are popularly utilized in heat recovery systems and heat pumps as they ensure uniform temperature distribution within their systems or pumps.

Parallel flow heat exchangers operate by having fluids moving in the same direction through it; this results in gradual equalization of temperatures along its length, producing more uniform temperature distribution that suits applications that demand tight temperature regulation and consistent control.

Difference Between Counterflow and Parallel Flow Heat Exchanger

Here are some difference between Counterflow and Parallel Flow Heat Exchanger:

- Heat Transfer Characteristics:

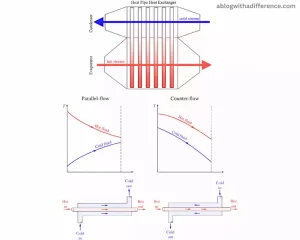

- Counterflow: Counterflow heat exchangers provide efficient heat transfer due to the continuous temperature difference between the hot and cold fluids. This results in a higher overall heat transfer coefficient.

- Parallel Flow: Parallel flow heat exchangers have a decreasing temperature difference along the length of the exchanger, leading to lower overall heat transfer efficiency compared to counterflow.

- Temperature Distribution:

- Counterflow: Counterflow heat exchangers maintain a large temperature difference between the hot and cold fluids throughout the exchanger, allowing for a more significant heat exchange.

- Parallel Flow: Parallel flow heat exchangers have a gradual temperature equalization between the fluids along the length of the exchanger, resulting in a more uniform temperature distribution.

- Pressure Drop:

- Counterflow: Counterflow heat exchangers generally have a higher pressure drop due to the opposing flow directions of the fluids.

- Parallel Flow: Parallel flow heat exchangers typically have a lower pressure drop compared to counterflow, which can result in lower energy consumption and improved system performance.

- Suitability for Different Applications:

- Counterflow: Counterflow heat exchangers are well-suited for applications where large temperature differences and efficient heat transfer are required, such as in power plants, HVAC systems, and certain chemical processes.

- Parallel Flow: Parallel flow heat exchangers are suitable for applications where a uniform temperature distribution is desired, and where the temperature difference between the fluids is relatively small, such as in heat recovery systems or some heat pump applications.

- Energy and Material Efficiency:

- Counterflow: Counterflow heat exchangers often require a smaller heat transfer surface area due to the large temperature differences, resulting in lower material requirements.

- Parallel Flow: Parallel flow heat exchangers may require a larger surface area for heat transfer compared to counterflow configurations, potentially increasing material and cost requirements.

Counterflow and Parallel Flow Heat Exchanger have their advantages and limitations. Counterflow heat exchangers excel in efficient heat transfer and large temperature differences, while parallel flow heat exchangers provide a uniform temperature distribution and lower pressure drop.

The choice between the two depends on the specific requirements of the application, including temperature differential, pressure drop constraints, and desired heat transfer efficiency.

Comparison chart

| Topic | Counterflow Heat Exchanger | Parallel Flow Heat Exchanger |

|---|---|---|

| Heat Transfer Characteristics | Efficient heat transfer due to continuous temperature difference between fluids | Lower overall heat transfer efficiency |

| Temperature Distribution | Large temperature difference maintained throughout the exchanger | Gradual temperature equalization between fluids |

| Pressure Drop | Higher pressure drop | Lower pressure drop |

| Suitability for Different Applications | Large temperature differences, efficient heat transfer | Uniform temperature distribution, smaller temperature differences |

| Energy and Material Efficiency | Lower material and energy requirements | Potentially higher material and energy requirements |

Conclusion

Heat exchangers are indispensable devices that facilitate the transfer of thermal energy between fluids. Counterflow and parallel flow heat exchangers are two prevalent types, each with its own set of advantages and disadvantages.

Choosing the appropriate heat exchanger depends on the specific application, efficiency requirements, and cost considerations.